Honourable Mentions

1st Prize - 2nd Prize - 3rd Prize - Honourable Mentions - Special Mentions - FinalistANAGASICA056

Project by: Ana Carolina Vargas González, Alexis Salinas Arriagada, Gilberto Valverde Arias, David Cubero Fernández.from Costa Rica and Chile.

Honourable mention selected by Kaira Looro & Balouo Salo organization

DESIGN IDEA

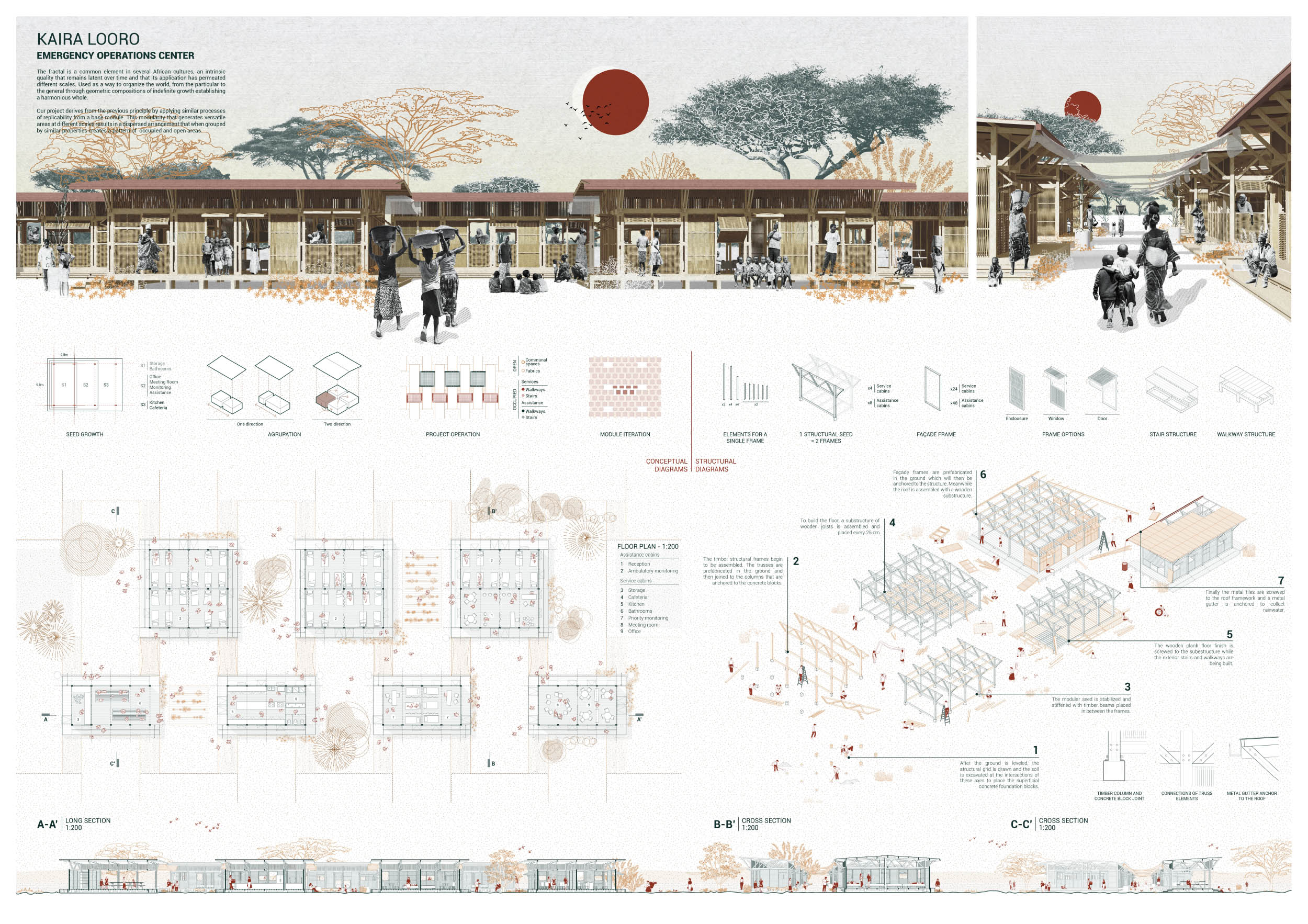

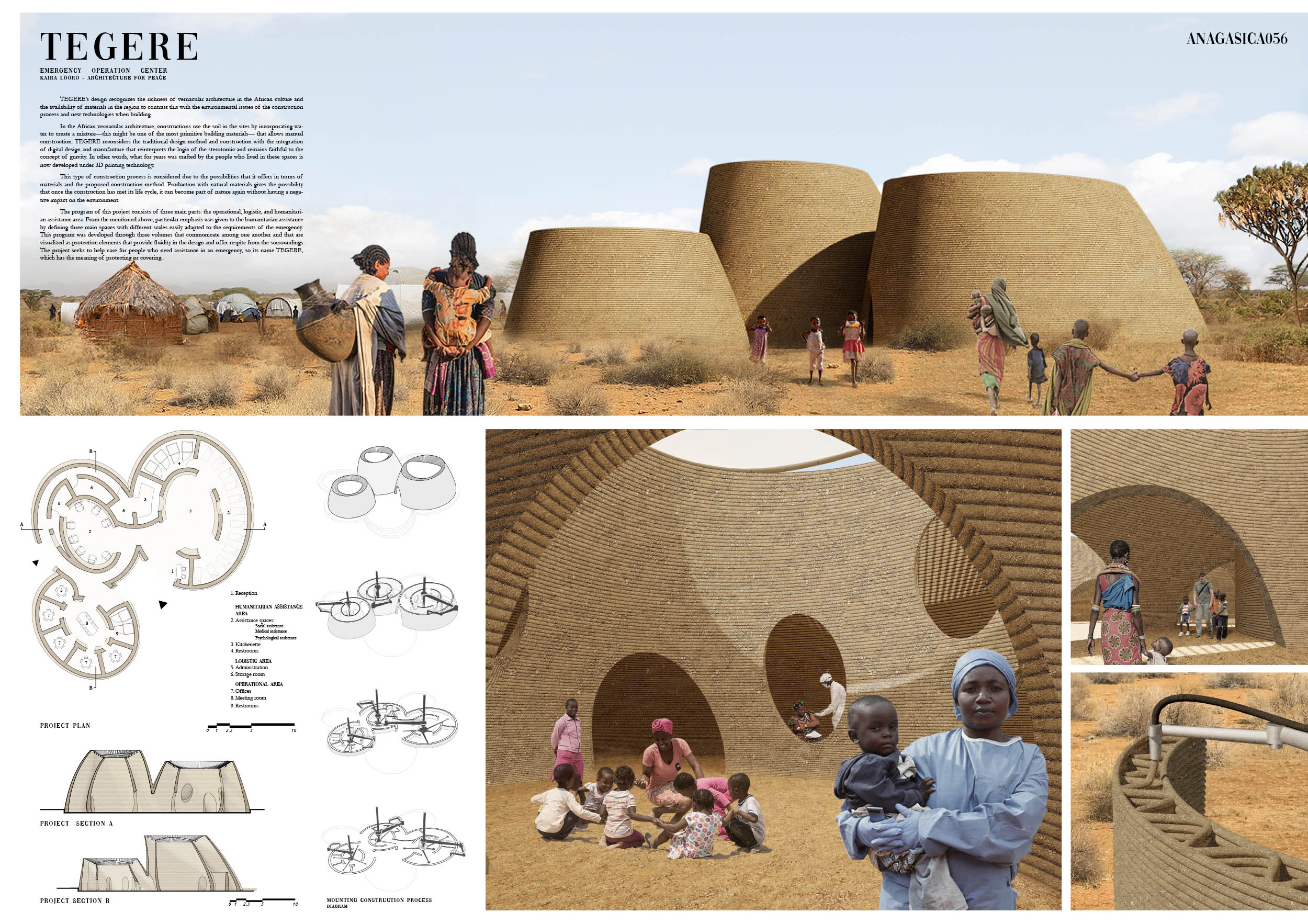

People are immersed in contexts that change and mutate differently due to human and non-human actions that affect their lives, and some are unexpected and lead to emergencies that show human vulnerability. Africa has not only been known for its natural and cultural richness but also for its emergency situations. Due to this, different organizations provide support and require the resources and equipment that allow them to work. In this context, a center for emergency operations is needed to provide the necessary support, and TEGERE comes to help in the process. TEGERE’s design recognizes the richness of vernacular architecture in the African culture and the availability of materials in the region to contrast this with the environmental issues of the construction process and new technologies when building. Based on this, a thorough study is conducted to analyze the previous factors. The study focuses on the traditional construction methods, the logic behind the location of the constructions, the benefits of natural materials, the importance of a sustainable development, and the new construction tools that are available. In the African vernacular architecture, constructions use the soil in the sites by incorporating water to create a mixture—this might be one of the most primitive building materials— that allows manual construction. TEGERE reconsiders the traditional design method and construction with the integration of digital design and manufacture that reinterprets the logic of the sterotomic and remains faithful to the concept of gravity. In other words, what for years was crafted by the people who lived in these spaces is now developed under 3D printing technology. This type of construction process is considered due to the possibilities that it offers in terms of materials and the proposed construction method. Production with natural materials gives the possibility that once the construction has met its life cycle, it can become part of nature again without having a negative impact on the environment. When manufacturing, time is fundamental and by means of 3D printing production, time is considerably reduced compared to traditional methods. Under this method, the way materials are brought to the construction site changes, and the application of parametric design determines the optimal and most efficient system to make this possible. At the same time, the implementation of the design process allows the exploration of the morphologies that evoke formal gestures that can be found in art and architecture in African cultures. Through this, the project intends to be easily identified by its users and integrated in the context of the area. Finally, the proposal expects to be a model for the management and response to different emergencies like natural, sanitary, and food emergencies and security. The program consists of three main parts: the operational, logistic, and humanitarian assistance area. From the mentioned above, particular emphasis was given to the humanitarian assistance by defining three main spaces with different scales easily adapted to the requirements of the emergency. This program was developed through three volumes that communicate among one another and that are visualized as protection elements that provide fluidity in the design and offer respite from the surroundings. TEGERE intends to be a model for emergency operations centers that is based on the geographical context by taking into consideration the natural and cultural richness, the requirements of the constructions for emergency purposes, and the available technology. The project seeks to help care for people who need assistance in an emergency, so its name TEGERE, which has the meaning of protecting or covering.USE OF MATERIALS

The main material that is used to build the walls and floors is a mixture of soil, water, straw, and vegetable-based additives. The preparation process is very similar to the traditional one that is used in Africa where the soil is extracted from the construction site, which reduces the economic and energetic cost to obtain the raw material. Once it is extracted, the soil is mixed with the other materials to obtain a stiff product that is later deposited in layers in an automated way to build the different volumes in the project. The project requires approximately 216 m3 of soil, which are collected by undermining -0.5 m of the site. The extraction of the soil is integrated into the design by adjusting the topology in the building site according to the location and landscape value. In terms of the covers, wooden structures will be used as the basic structure upon which a waterproof cover will be placed.MOUNTING / CONSTRUCTION PROCESS

The construction process is carried out by means of 3D printers, and it starts by preparing the land, extracting the soil, installing the printers, working on the material to print the walls, and it continues with the deposit of layers of the material in an automated way, with specific speed and consistency to give shape to the building. Approximately, the printing of 0.15 m of wall is about 1 second. However, the preparation time of the mixture and installation of the printers must be added, which gives a construction time of 141.4 hours (Continuous Work Days -24hrs- 5.9 Total Days, or in Partial Work Days -12hrs- 11.8 Total Days). The manufacturing process that uses soil 3D printing posts significant advantages. For instance, in a catastrophic scenario, it would help people with the hard work in any construction while the architectural features are still taken into account. Additionally, the costs are reduced because builders have easy access to the resources in the building site, the soil as raw material and printers that use solar panels, which provides constant progress and helps in the construction time.ELAINABIA971

Project by: Manuela Molina, María Camila Joaqui, María Camila Martínez, Silvia Valentina Ruiz.from Colombia.

Honourable mention selected by Kengo Kuma